Rapid-Lok® Connection Plate System

What is Rapid-Lok?

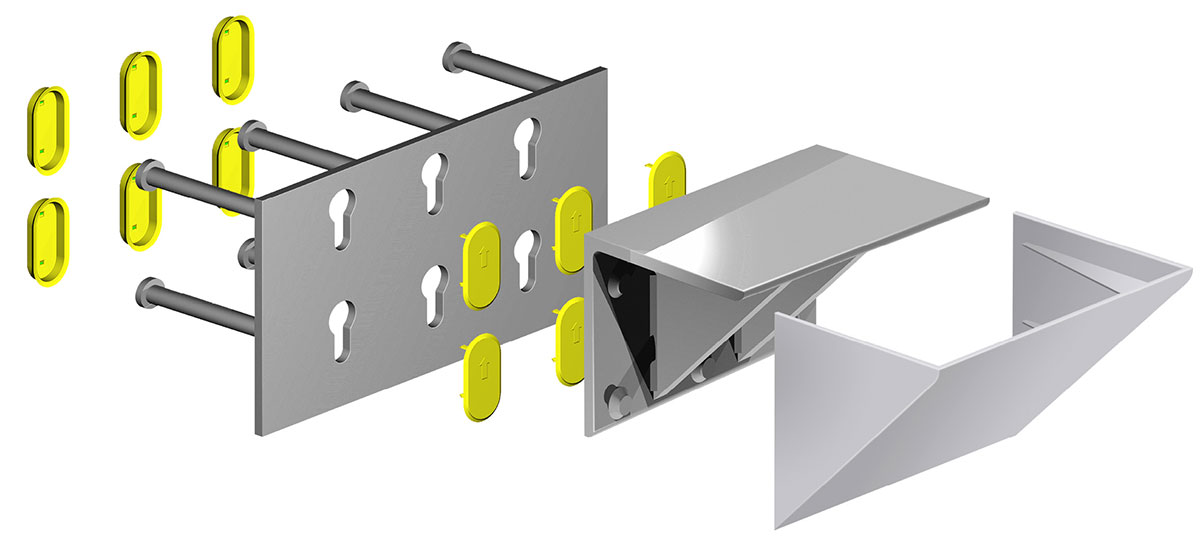

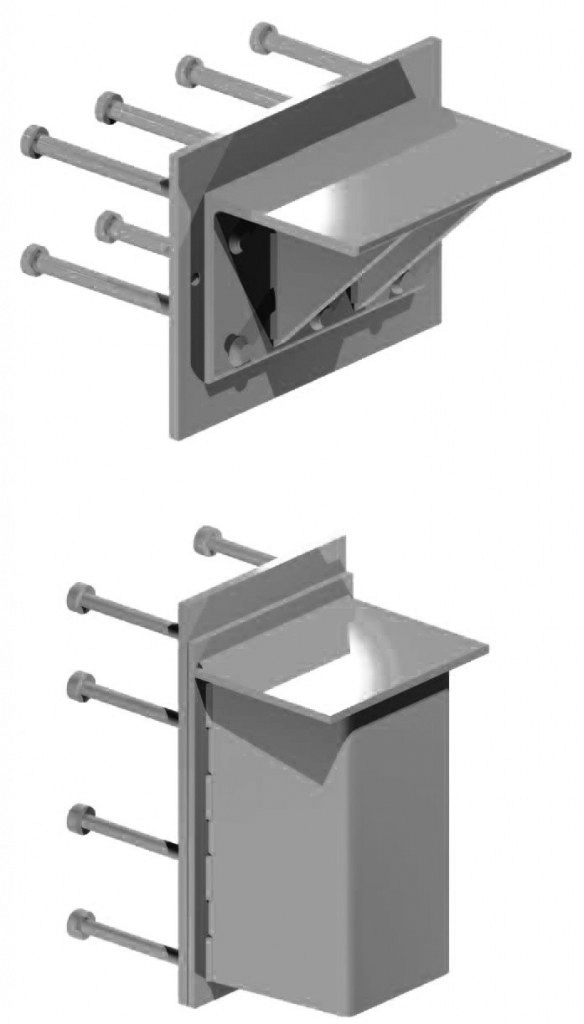

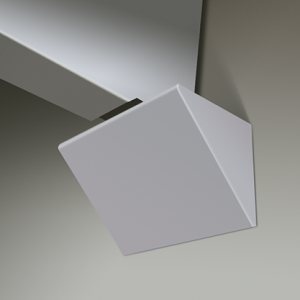

Rapid-Lok is used to eliminate the conventional concrete corbels. Rapid-Lok system creates a steel projection in a structural wall, which acts as shelf able to carry a weight of Double Tee, Stair, Beam and other precast elements. Rapid-Lok system consists of A Bearing Angle, Concrete Replicated Bearing Corbel or Steel Corbel that lock into an Embed Plate cast into the structural wall.

How it Works

Rapid-Lok Embed Plates are cast into the precast wall at the precast plant, with the faceplate flush with the outer wall face. Once on site, the void formers attached to the face of the Embed Plate are removed by the Erector to reveal ‘keyholes’. The Bearing Angel or Bearing Corbel’s interlocking studs are then dropped into the keyholes of the Embedded Plate, securely locking them in place without requiring a weld. A Bearing Angle would be used when the steel angle can be left exposed or covered over with the Rapid Lok cover. The Bearing Corbel would be used when an ‘encased’ finish is required and when a higher fire rating is needed.

Features

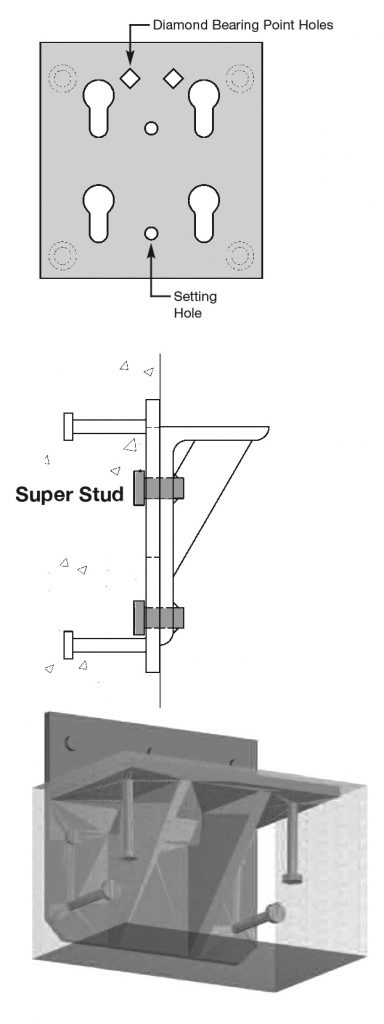

Rapid-Lok features “Diamond Hole” that are used to locate the “Bearing Point”. These are through holes, visible from either side, even after galvanizing.

Setting Holes aid in the installation process, are .562” in diameter and consistently located for use with templates during production.

The Safe Working Load of the device is located in the corner of each Rapid-Lok. This indicates the unit’s SWL; installation conditions and location may reduce the actual SWL.

“Super Studs” attached to the Bearing Angle and Bearing Corbel have been “cold tested”, configurated and sized for optimum performance in all weather conditions, ensuring the load bearing capacities are met.

Rapid-Lok system feature hot dip galvanized finish per ASTM A153. Rapid-Lok system was fire tested per ASTM E119.