Rapid-Lok Ultimate

What is Rapid-Lok Ultimate?

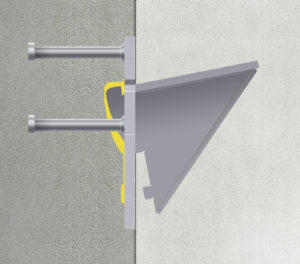

Rapid-Lok Ultimate creates a steel projection from a concrete structure which acts as a shelf, able to carry the weight of a double tee.

Rapid-Lok Ultimate creates a steel projection from a concrete structure which acts as a shelf, able to carry the weight of a double tee.

How Rapid-Lok Ultimate Works:

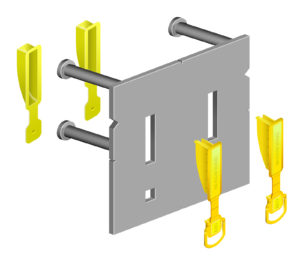

The Embed Plate is cast into the concrete structure at the precast plant, with the faceplate flush to the wall face. Once the precast wall is on-site, the void formers attached to the face of the Embed Plate are removed to reveal recesses.

The Bearing Angle ears are then engaged into the recesses and the Embed Plate, securely engaging them in place without requiring a weld.

Rapid Lok Ultimate is available with an 8-inch or a 10-inch bearing plate.

Benefits of Rapid-Lok Ultimate:

- Labor efficiencies from simplified panel forming

- Safety improvements by minimizing injuries

- Cost reductions in transportation and dunnage

- Increases erection efficiencies

Who Uses Rapid-Lok Ultimate:

Who Uses Rapid-Lok Ultimate:

Structural Engineers

- Capacity rating using ultimate loads aligning with current design methodology

- Consolidation of models and capacity ranges for simpler design selection

- Load tested to ACI-318’s 5% fractile to meet current code requirements

- Fire rating for 3 hours and tested per ASTM-E119

Double Tee Producers

- Labor efficiencies optimized by simplifying panel forming

- Safety records improved by minimizing injuries

- Cost reduction in transportation and dunnage

Architects and Consultants

Architects and Consultants

- Fluid feature in the finished structure emulating a concrete cast corbel

- Potential cracking with traditional concrete corbels is eliminated

Erectors

- More efficient installation by avoiding obstructions from preinstalled concrete corbels

US Patent No. 10,883,265